Shibaura Machine India is a wholly owned subsidiary of Shibaura Machine Company of Japan.

Shibaura Machine India is at par with global standards of manufacturing excellence, quality control & customer support.

Our Sales and Support team are here to help. Connect us via appropriate channel for faster support.

Shibaura Machine India Private Limited has decades of experience in plastics injection moulding machinery segment, helping hundreds of companies around the world to mould products with precision & speed, offering very high quality of output.

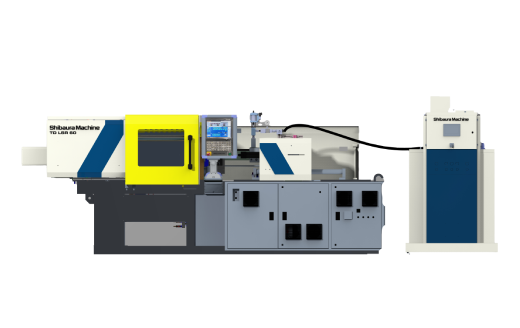

Shibaura Machine is among the leading high-end plastics injection moulding machines and auxiliary equipment manufacturers in India.

Top-of-the-line manufacturers & exporters of plastic injection moulding machines in India.

Faster, Cleaner, Quieter – Energy saving All Electric Injection Moulding Machine

Special Application Injection Moulding Machine

Complete range of Auxiliary Equipment for plastic Processing Industries.

The world’s best High Pressure Die Casting Machine for processing of Aluminium and Magnesium.

Shibaura Machine India is a globally reputed manufacturer in the field of Injection Moulding Machines and Auxiliary Equipment. Our decades of experience help us stay resourceful to our clients.

Since 1991, Shibaura Machine India has a global reputation in the field of Injection Moulding and Auxiliary Equipment

Shibaura Machine is one among the names behind Japanese Revolution

Operating Lean & Clean and yet global in our standards across strategic locations.

We continue to learn and stay resourceful for serving our customers only the finest

Shibaura Machine has been winning laurels for manufacturing excellence

Ever since founding, Shibaura Machine has been consciously working on sustainability.

We view the future with you.

24/7 access to our network of support channels.

Training program for manufacturing excellence, standard and processes.

Stockist are spread all over the India to support spare part supply

Shibaura Machine is available 24/7 to serve our customers better. Connect with us on the below contact modes.

+91-91500 21901 sales@shibauramachine.co.in

+91-91500 63555

service@shibauramachine.co.in

service.export@shibauramachine.co.in

Shibaura Machine India Pvt. Ltd is a High-end plastics injection moulding machines and auxiliary equipment manufacturers in India.